● Plastic Injection Tool Design

At Triple D Design once we have finished designing your plastic part we can also design the injection mould as part of the process. All plastic parts are very carefully designed to assist the moulding process and considerations of the materials used and the properties of the moulding machine can be taken into account. We have a large range of standard injection mould components on file in our CAD software to quickly produce working tool designs ready for fabrication.

Tooling Design

● Blow Mould Tool Design

Blow moulded parts are very carefully designed to assist the moulding process. All considerations of the process are examined including the materials used for the part and the mould, the required shape, the attributes of the part and the properties of the moulding machine.

● Vacuum Forming Tool Design

Triple D Design has been involved in a range of vacuum forming projects producing tooling in materials such as composite, epoxy and machined aluminium. Part design, part draft and application are considered when designing the tooling to ensure the parts are easily mouldable and the tools can handle many moulding cycles..

● Composite Tool Design

At Triple D Design many key design considerations are examined when working with composite tool designs. These considerations include material selection, fabrication method, structural considerations, part draft and required runoff. On complex multi-draft designs, undercuts can be handled by adding removable pieces to ensure the parts can be released from the mould with ease. Vacuum channels and angled runoff faces can be added to aid the fabrication process.

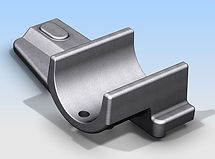

● Cast Aluminium Tool Design

Triple D Design has produced many tools for aluminium casting including gravity and low pressure tooling. We are able to design patterns for sand casting as well as patterns for cast iron tooling to be CNC machined to the final mould shape. When required tools can be produced with undercuts and removable cores when working with more complex shapes. Material volumes and weights can be calculated and factored into the design when cost and final part weight are a concern.